Regular readers here know I’m passionate about exploring sustainable solutions, from the food we eat to the energy we use as well as uncovering those unexpected sustainability individuals who are simply doing right by our planet. In the UK, we’re facing a dual challenge: creating warmer, healthier homes and significantly reducing our carbon footprint. The good news? We have the skills, tools and materials readily available to achieve both, particularly through sustainable building practices. The frustrating part? For some reason, we’re still not utilising these incredible resources, especially when it comes to larger-scale housing developments.

I recently had a fascinating conversation that opened my eyes and really brought this home. My guest, Will Stanwix a.k.a. ‘That Hempcrete Guy’, a pioneer in the world of natural building, shared his journey and insights, highlighting just how much potential we’re sitting on. Another unsung hero quietly championing the use of carbon-negative hempcrete to revolutionise eco-friendly construction and reduce humanity’s environmental footprint.

Listen to this audio introduction from me.

From Straw Bales to Hempcrete: A Journey into Sustainable Building

Will’s passion for alternative building methods began at Kingston University, where one really good lecturer ignited his interest in sustainable building and historic buildings. This led him to discover straw bale building at Eco Build (now Future Build), thanks to two visionary women, Bee Rowan and Barbara Jones, the pioneers behind “Hammers and Nails” or if you ask them to pronounce it, that’s “Amazon Nails” in a Yorkshire accent!.

Straw bale buildings present practical challenges Will explained to me “The straw bale is really cheap and really easy, but everything else is really difficult. Imagine trying to run electrics through straw bales or plaster a pillow-shaped bale to make a perfectly straight wall!” So, while affordable, it often leads to increased costs in other areas.

This led him to discover hempcrete through a course at the Low Impact Living Initiative. Professor Tom Woolley, an architect who had experimented with it in Ireland, had written a small book on the subject. Intrigued, Will built his first hempcrete extension for a neighbour and was instantly hooked. “It’s just so intuitive, and it’s really easy and straightforward, and the detailing is really simple,” Will enthused.

What began as a one-off project soon became a business. Initially, he designed hempcrete buildings, but found a lack of builders willing to work with the material. Some large commercial projects were being built with hempcrete – like Marks & Spencer and Adams Brewery – but small, domestic builds were scarce. So, he took matters into his own hands and started building this way himself, promoting that through what seems to me to be his aptly titled website ‘thathempcreteguy.com’ .

The Gradual Shift: From Pushing to Being Pulled

Over the past 15 years, the adoption of natural building materials has been a gradual process, progress in construction is notoriously gradual. “Things in construction tend to be really gradual,” he noted. “Everyone’s so… frightened, so they want to see that someone’s done it before them and that it’s worked.”

Back in 2008, he knew of every hempcrete building in the UK and had built half of them! Today, the landscape is much different. While still a niche, there are now a good ten or so natural builders specialising in hempcrete, and many more traditional builders are taking on projects when clients request it. The days of actively “selling” the idea at events like Grand Designs Live are largely over; the shift is palpable: “Back then you were having to persuade people to use it, whereas now I’ll get phone calls: ‘My architect’s designed a hempcrete house, can you come and build it?'”

The Roadblocks to Large-Scale Adoption

This brings us to the crux of the problem: if the benefits are so clear, why aren’t these incredible natural materials being used in large housing developments? The answer, unfortunately, boils down to profit and ingrained processes. Developers are driven by speed and cost-efficiency. They won’t adapt their meticulously choreographed building processes unless there’s a compelling reason, usually driven by legislation.

Training an entire workforce in new methods is an upfront cost they’re unwilling to bear when cheaper, albeit less sustainable, alternatives are still permitted. It’s like a well-oiled machine; changing one cog requires re-engineering the entire system. Training an entire workforce in new methods simply isn’t deemed profitable.

This highlights a critical point: legislation will be the key driver of change. Current building regulations heavily focus on “energy in use” – how much carbon a house emits once built. We’ve largely maximised what traditional building can do in this area, with solar panels, air source heat pumps, and high insulation values becoming standard.

However, the next frontier, and where natural materials truly shine, is embodied energy of materials – the carbon emitted during the production and transport of building materials. Government and commercial buildings are already starting to incorporate this, and it’s anticipated to eventually become part of building regulations, albeit slowly. “In the last 15 years, the energy in use has got to the point where now you can’t do any better. So if they’re starting now with the embodied energy, in 15 years’ time, 20 years’ time…”

The Carbon Capture Revolution: How Natural Materials Work

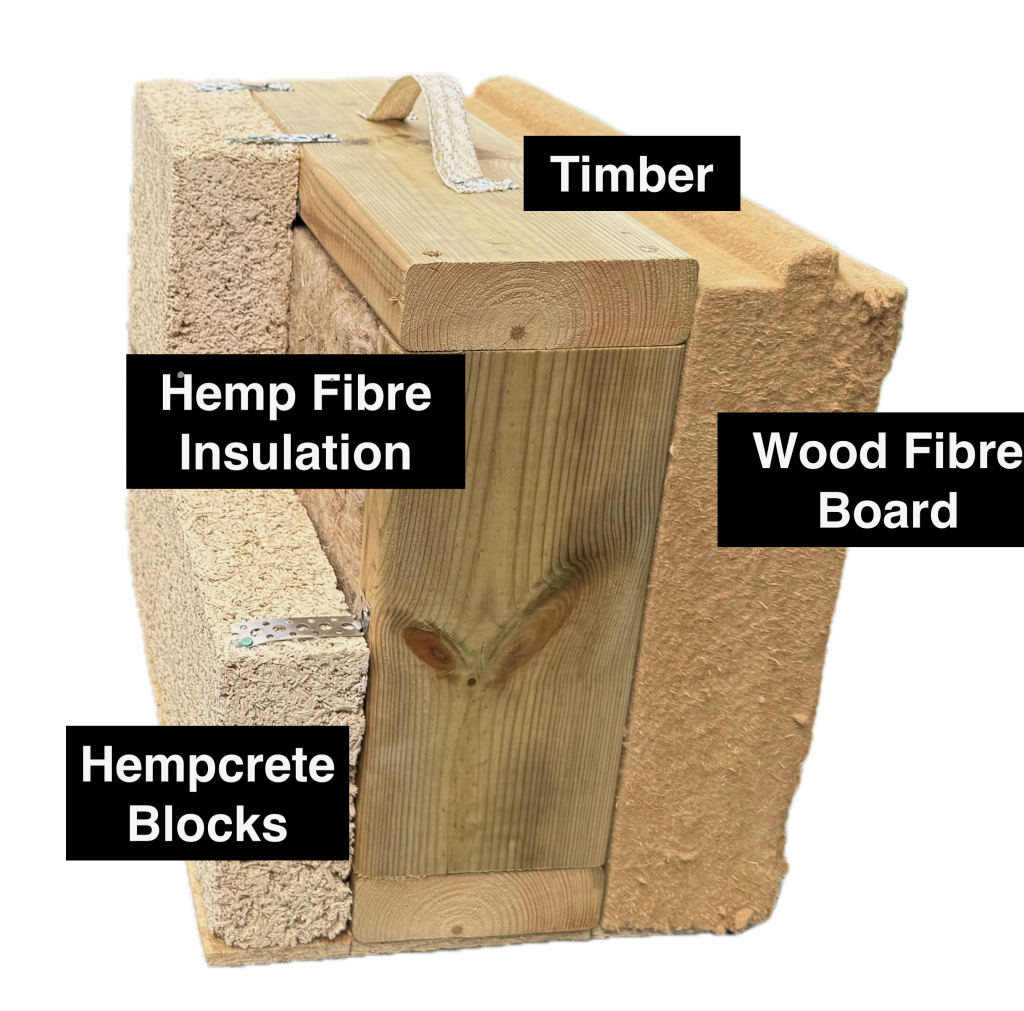

This is where the magic truly happens with natural materials. That morning Will had built a model to explain a cross-section of a wall made with wood, hemp, and lime which was really helpful to my understanding not just of its carbon capture abilities but its other qualities too. Here’s how it goes:

- Timber: As trees grow, they breathe in carbon dioxide and convert it into carbon, which is then fixed within their structure. As long as the wood isn’t burned or allowed to rot, this carbon remains locked away for the lifespan of the building.

- Hempcrete Blocks: These are made from hemp shiv (the woody core of the hemp plant) and lime. While lime production involves burning limestone, the lime used in hempcrete actually reabsorbs carbon from the atmosphere as it sets, making it far more carbon-friendly than cement. The lime brings benefits of its own but does reduce how much carbon is locked away within it – still its more than is used to make the block.

- Hemp Fibre Insulation: The fibrous part of the hemp stalk, also used for textiles, acts as an excellent insulator and, like timber, locks away atmospheric carbon.

- Wood Fibre Board: Used as external wall insulation, this material alone can lock up to 150 kilograms of carbon per cubic metre!

And just to push a point, these products lock up the carbon for as long as the building stands of course – potentially hundreds, even thousands of years!

Crucially, these are all crop-based materials. Hemp, for instance, grows incredibly fast – about 14 feet/4 metres in 90 – 120 days – acts as a natural weed suppressor because it quickly covers an area, reducing sunlight through shading and preventing weed seeds from germinating. And its deep roots enrich the soil, improving aeration and drainage, bringing nutrients from deep layers to the surface. This means it can be integrated into existing crop cycles without impacting food production. This is getting really interesting!

And it’s not just walls that lend themselves to alternative natural construction, it’s possible for all building elements. Will converted a Barn on his property, ‘The Old Wheel Wrights’ Barn, a perfect time for him to experiment a little and check out the results.

The Barn Floor : Will used glass foam insulation which is recycled glass melted down and made into a very lightweight material that is like pumice stone. It’s laid down like a gravel and compacted. The barn has a 250mm thick layer of it. Once compacted you usually put a limecrete screed over (with under floor heating pipe in). In the barn he instead laid hempcrete blocks over and then a wooden floor over that. Check out his Instagram post HERE

The Barn’s Roof: Here Will insulated the roof, both thermal and acoustic, using sprayed hempcrete, but instead of using lime as the binder he used clay. This was an experiment to see if clay worked. Why? By using clay rather than lime it further reduces the embodied carbon as clay powder is not burnt in its production like lime. It worked! He has two YouTube video’s you can watch HERE and a second one once he was finished HERE.

Fuelling a Greener Future, One Story at a Time. Every small step we take – from reusable bags to conscious consumption – ripples outwards, creating a wave of hope. Let’s rewrite the story of our planet, one click at a time. I believe in the power of storytelling. By sharing inspiring environmental initiatives, unsung sustainability heroes and practical tips, I aim to amplify the voices making a difference. Imagine a world where everyone is empowered to take action, one small change at a time. ‘Buy Me A Coffee’ donation is a quick and easy way to offer a small, one-off donation, that helps keep this platform running and allows me to continue sharing these vital stories. Just click the “Donate” button (top right corner). Every contribution, no matter the size, makes a difference. Thank you for being a part of this journey.

Beyond Carbon: Health, Comfort, and Fire Safety

The benefits of natural building extend beyond carbon capture:

- Healthier Homes: Early clients came to Will with severe allergies to chemicals found in typical building materials. That’s because modern homes, often packed with petroleum-based products, can suffer from “sick building syndrome” due to harmful off-gassing. Natural materials, however, create a much healthier indoor environment, free from those airborne toxins. If you want to get really scared about how many toxic chemicals our buildings are made from, the previously mentioned Professor Tom Woolley’s book is HERE

- Superior Insulation and Airtightness: A hempcrete wall can offer over 300mm of thermal protection, very simply, making it easy to achieve incredibly airtight buildings. This means significantly less energy spent on heating! Will’s own home, for example, hit an astonishing 0.7 air changes per hour in an air test. For context, 0.5 is Passive House standard, 5 is typical for new builds!

- Fire Resistance: Despite being organic, natural materials like hempcrete are surprisingly fire-resistant. Hempcrete blocks are fireproof to Class B, meaning they won’t flame up or produce smoke. If they do burn at extreme temperatures, it’s a slow, smouldering process, giving plenty of time to evacuate – a stark contrast to many flammable, fume-releasing petrochemical insulations.

- Vapour Permeable Walls: This is where natural materials truly shine. Almost all natural materials are inherently vapour permeable, making perfect sense as they’ve evolved to manage moisture in nature. Think of high-tech hiking boots that keep your feet dry from rain but also let sweat escape – that’s vapour permeability at work! This allows your walls to regulate humidity, preventing condensation and avoiding mould and damp. Good luck getting man-made materials to do that without a huge cost!

The Challenge of Skills and the Promise of the Future

One of the main perceived challenges is the availability of skilled labour, particularly for lime and clay plastering. While these are indeed specialised skills, they are not inherently difficult for a traditional plasterer to learn. “It’s exactly the same skills,” Will affirmed, “It’s just different material.” The reluctance often stems from a fear of the unknown. However, as more builders gain confidence, the availability of these skills will naturally increase.

The speed of construction isn’t necessarily a barrier either. Timber frames, often used with natural insulation, go up incredibly quickly. “We put the whole timber frame up in two days,” he recalled about a recent project.

Conclusion: The widespread adoption of sustainable building practices in the UK will require a shift in mindset, driven by both market demand and, crucially, legislative changes. As the government continues to focus on embodied energy in materials for commercial and public buildings, it’s only a matter of time before these standards trickle down to residential developments. It’s time for the UK construction industry to truly embrace these proven tools and materials building a future that’s sustainable for generations to come.

Want to Know More?

Here’s a super case study, a children’s nursery Will built in Bellingdon. A large new build constructed predominantly in earth and hempcrete with NO concrete or cement, even in the foundations that were built using flint rubble taken out of the soil from the surrounding fields! With 3 Buckinghamshire design awards to its name, it’s worth a look HERE at the photographs.

And Will’s book about Hempcrete can be purchased HERE

LINKS:

- Portfolio website thathempcreteguy.co.uk

- Hemp blocks website hempblock.co.uk

- Clay plaster website clay-wall.co.uk

- @william.stanwix on Instagram

- @williamstanwix on YouTube